COMPANY

ISC ltd, founded in 2015 to provide industry and communities with quick and reliable solutions in the fields of water treatment, textile industry, food sector, wood, non-woven, pulp and paper and gas treatment.

Our technicians experience offers quality products tailor made for your business need.

ISC ltd provides technical commercial assistance with international presence with a rapid and complete service. Our goal is to provide comprehensive technical application expertise to your company filtration requirement.

We will assist you to decide and evaluate the market offer available for your application.

Thanks to our international activity, our experience and knowledge will be the tool for your saving. Cooperation with majority of Europe target OEM in AIR and Liquid filtration give us the ability to take care of individual requirements and concerns in the most efficient way.

We will assist your technical department with the choice of the right product. ISC provides comprehensive technical application expertise to your company filtration requirement. In a market full of unknown suppliers and fabricator of all sorts, we will advise you the best option.

Due to our international activity, our experience and knowledge will be the tool for your saving. Cooperation with majority of Europe target OEM in AIR and Liquid filtration give us the ability to take care of individual requirements and concerns in the most efficient way.

We will assist your technical department with the choice of the right product.

ISC will provide your company different options to better help you decide what to choose.

Our consultation service to your company is completely free.

The service we provide is to help your company to find the best solution on the market for your filtration need. What we guarantee is to give yo the most reliable product at the best price for your business need. We partner with some of the best manufacturer and OEM in the market for the best service and product.

Innovative “tailor-made solutions” in air and liquid filtration and environmental technology. For many years, our diverse range of products and services for industrial filtration have created a longstanding relation with customers. Our focus is to offer tailor-made solutions that suit our customers.

- From maintenance and revision of filter systems, a modular or individual

- Our expertise is an innovative filtration processes

- Analysis and research techniques to respond to your requirements…

- Measurement of permeability

- Dynamometric mechanical and elongation testing

- Chemical analysis

- Conductivity tests on media and ATEX certification provided

- Internal laboratory analysis

- Partnership with specialist laboratories (Mineralogy, Organic Chemistry)

- filter system construction to production and the sale of filter media and spare parts to turnkey projects we have the service and product you need.

- Incineration (domestic, industrial, special, hazardous and hospital waste, WWTP sludge)

- Mineral industries (cement, concrete, lime, plaster, coating plants, etc.)

- Iron and steel industries, steelworks, metallurgy, aluminium

- Food processing (sugar factories, distilleries, animal feed plants)

- Chemical industry, refineries, pharmaceutical and cosmetics products and laboratories

- Glass industry

- Wood, paper and board industries

- Water treatment and sludge dewatering (drinking water, urban and industrial waste water)

- Surface treatment (shot blasting, sand blasting, liquid and powder painting booths, anode bags, filtration of baths, effluent treatment)

- Air conditioning

- Air treatment

- Air distribution

We are expert in the maintenance of all the main filtration equipment.

The process consist in assess the equipment and evaluate together with the customer the best solution.

We aim to have the best product and service to the lowest price for you.

WHAT WE SELL?

PRODUCTS

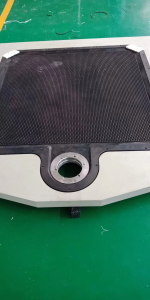

- FILTRATION EQUIPMENT

- SPARES

- SEPARATION OF LIQUIDS

- AIR FILTRATION

- PHARMACEUTICAL

- GAS TREATMENT

- FILTER CARTRIDGES FOR AIR, OIL AND NATURAL GAS

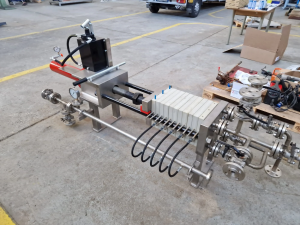

Original new and refurbished machinery for separation applications.

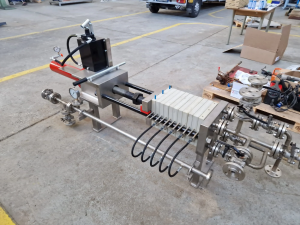

ISC cooperate with many European OEM to supply the highest quality equipment new and refurbished for your needs. We supply of Filter press pilot unit for on site process study and elaboration.

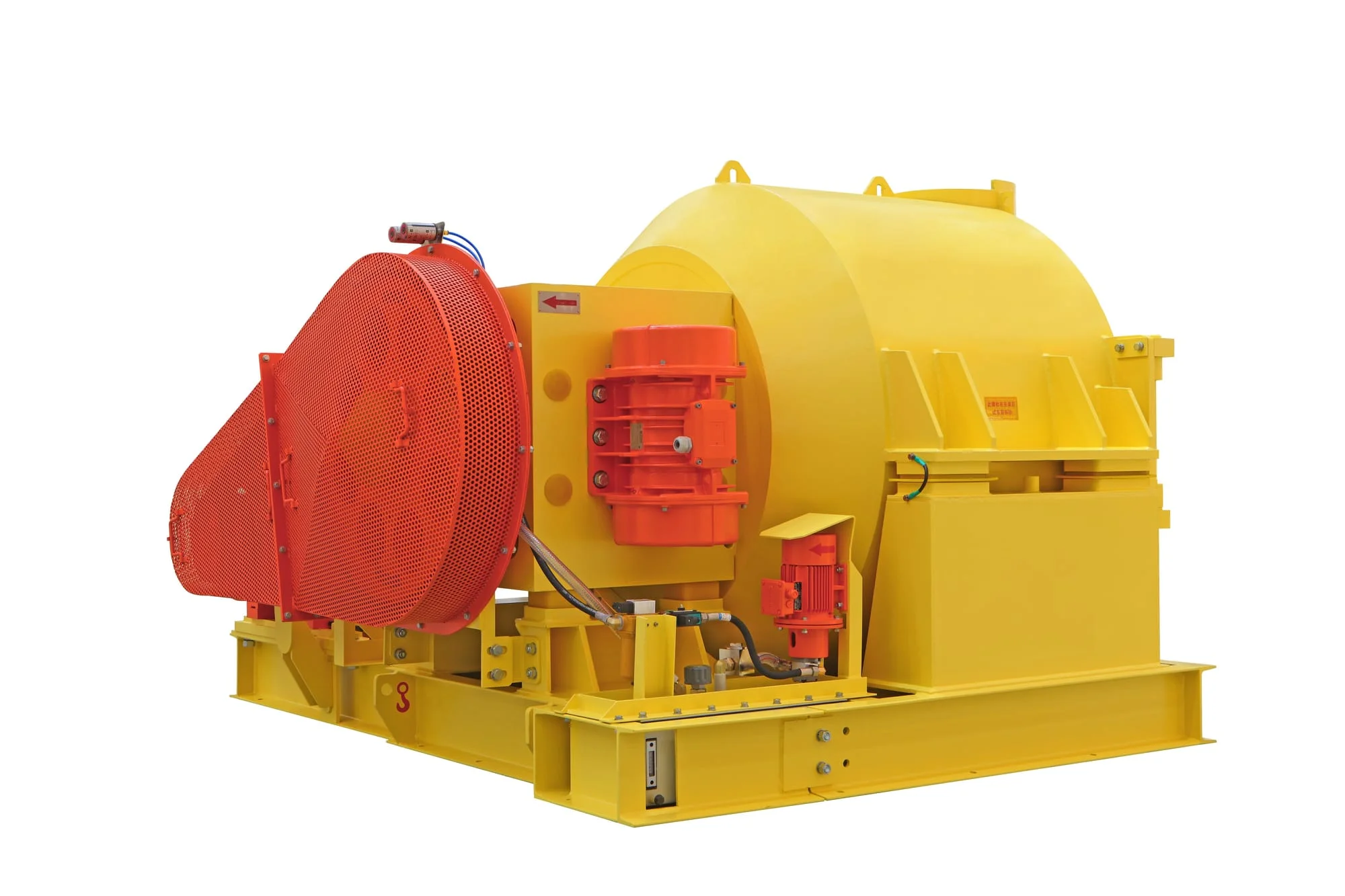

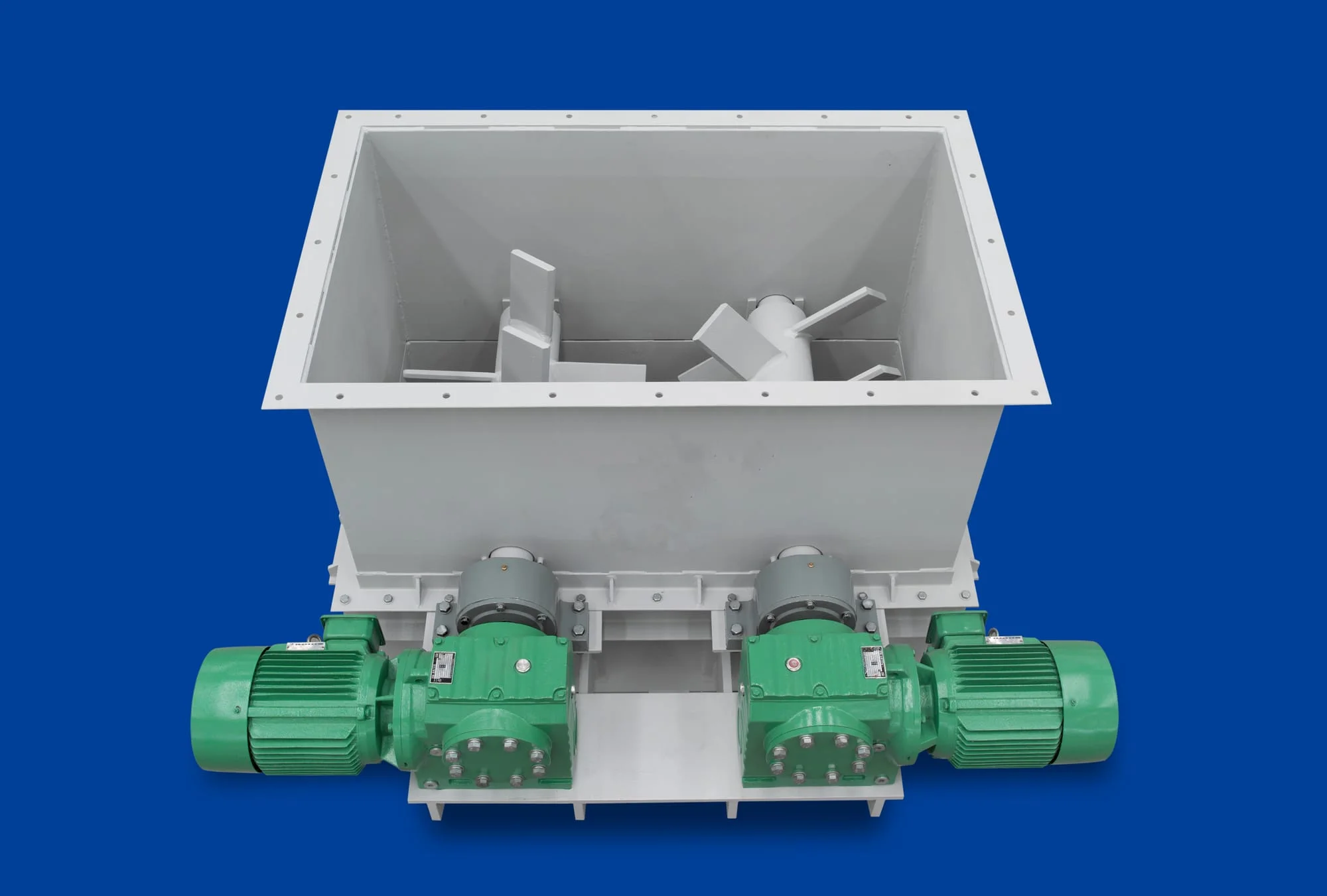

ISC represents some of the European OEM for filter press and related equipment; we make sure to supply the highest quality equipment new and refurbished for your needs. Filter press, Agitators, Centrifuges, Dosing machine, Scrapers, Cake crushers, Screw press, Screw conveyor, bag houses and other filter equipment for all markets covered.

Our filter press are produced in Italy with the highest standard materials.

We will assess your need free of charge from scratch to quotation stage.

All aspect of the full installation can be realized.

Applications:

- Pharmaceutical

- Agricultural

- Chemical

- Food & Agricultural

- Paper Scrap Trim Transport

- Laser / Plasma Cutting & Welding

- Rubber

- Composite / Fiberglass

- Mining

- Powder Painting

- Wood

- Textile

Plates, cages, valves and all other spare for your equipment.

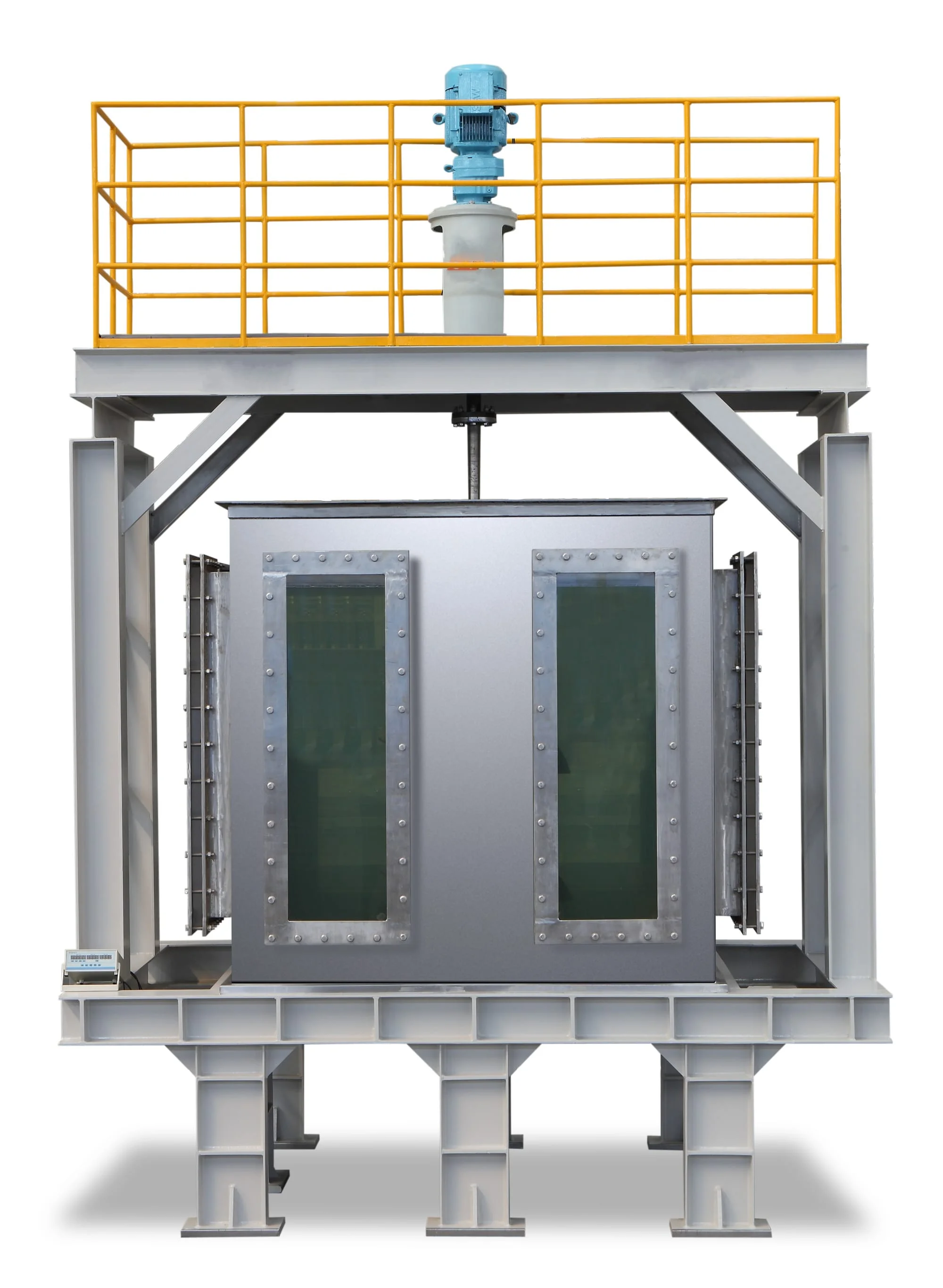

We are specialized in supply filter plates for horizontal filter press

Our production and distribution to serve the European market by offering a logistics base located in Italy and Portugal.

We can offer a delivery time of 12 to 14 weeks for delivery of 100% virgin polypropylene plates.

The size range available varies from 250×250 mm up to the wider 3200×2800 mm. Our filter plates are made by the process of die-casting/injection of pure polypropylene high density H.D.P.P.

Full range of spares for the liquid filtration and separation applications.

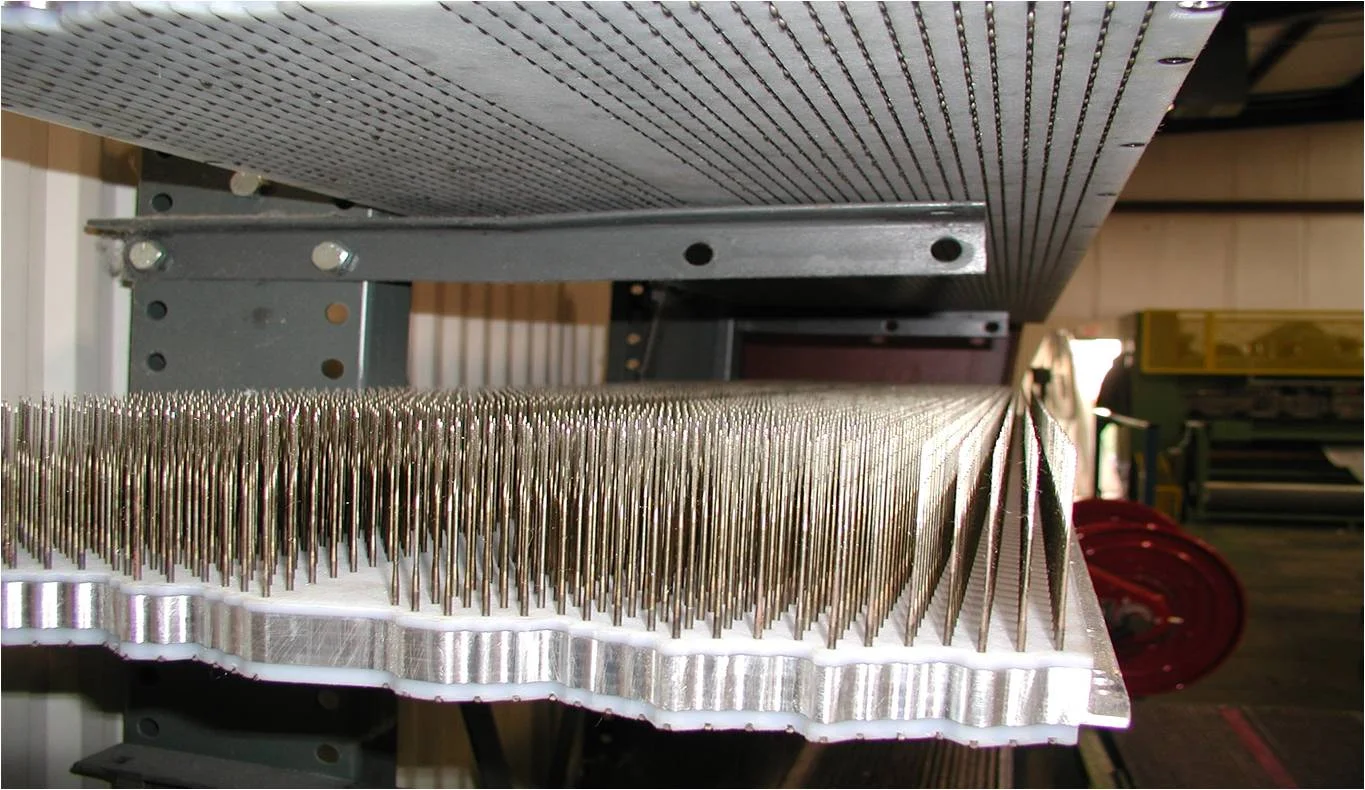

We have developed a particular range of cloths to be used in the food sector.

We also supply filter press plates in various materials and for any type of machine, produced in EU with a fast delivery time.the entire range of synthetic cloths for the dehydration of sludge produced in civil and industrial or process purification plants present in chemical/mining plants, dewatering, food pharmaceutical and other applications.

We also supply filter press plates in various materials and for any type of machine, produced in EU with a fast delivery time.

Filter sleeves and other elements

We produce all kind of filter bags and sleeves by the request of the customer (size, shape, quality).

We have a wide range of materials which we use in manufacturing:

- Polyester

- Polyester anti-static

- Polypropylene

- Meta – aramid

- Nomex

- P84

- PPS

- Blended products available

ISC only use materials from European manufacturer.

Hundred years of tradition in making fabric in this company is guarantee of quality for reasonable price.

Beside manufacturing, we offer technical support in cooperation with engineers from Italy.

Leakage test available on request.

Full range of elements for the PHARMA industry

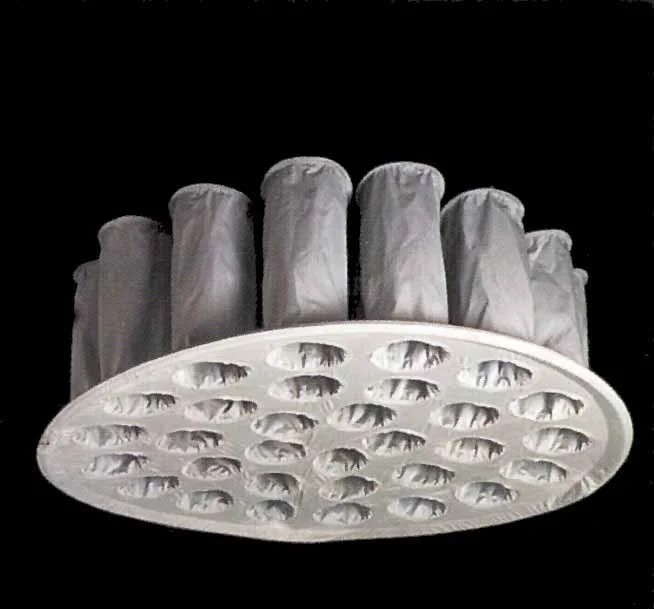

Filter bags Filters for fluid bed dryers – “octopus” filters with a large number of journals Bags for centrifuges Dry disc filters Gaf filters

We offer a number of filtration bag solutions — from pulse jet dust collectors and shaker dust collectors to blower units and fluidized bed dryers — for numerous industries and applications.

Reduced product loss – Increased safety – No product contamination from loose fibers – Optimal service life – Maximum performance– Highest dryness results – High production rates – Maximum machine running time – Perfect bag installation – Easy cleaning and solid release – Broad variety of applications

Tube – New: welded tubes (without stitching holes) to minimize product loss – Conductive fabrics – Standard diameter 160 mm

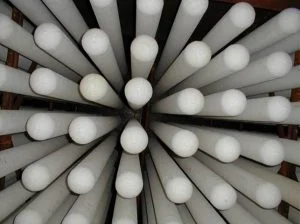

Cereamic candles elements for hot gas filtration

ISC supports the sales in EUROPE of ceramic filter elements

ISC supports thesales in EUROPE of ceramic filter elements designed to work at high temperatures (up to 900°C, maximum recommended working temperatures 600°); we also assist your business with replacement of any high temperature filter element. These elements can also be supplied with a catalyst for NOx, VOC, Dioxin abatement.

We can supply complete systems or the essential parts for SNCR/SCR systems to be used in the abatement/reduction of NOx in exhaust gases.

Our technology can be used in various sectors, such as:

- Production of glass or similar

- Waste-to-energy plants

- Crematoriums

- Diesel/biogas/heavy oil engines

- Boilers

* We offer filters and filter cartridges in special dimensions and quality, by the client request.

Oil separators Air separators Replacement filters from the most famous manufacturers such as D. Hunter, Pall, Hydac, Spirax Sarco, etc. Filter cartridges for natural gas filtration Cartridges for air filtration Cartridges for oil filtration Fuel filters Filter cartridges for the oil vapors treatment Filters for vacuum pumps Filters for compressors Cartridges for gas turbines and collectors of fine dust Cartridges for natural gas The cartridges are used to filter methane gas in the 1st, 2nd, and 3rd intervals in decompression cabins. They have a filtering capacity of 5 microns and great accumulating capacity; the filtering fabric is BIA-USGC certified, and it is thermostabilized from the input side for better removal of powders. They protect natural gas regulating and measuring equipment from mechanical erosion by powders. Technical specifications Filtering separator – polyester needle punched felt Degree of filtration – 1-3-5-20-50-100 mikrons nominal on the 99% of particles Adhesive – epoxy bicomponent Washer – pressed felt Collapse pressure – to request Max temperature – 135 °C Caps – powder coated RAL blue 5015 steel Support net – galvanised iron

FARMING AND AGRICULTURE

We are finalizing our development new 100% natural method for

the neutralization of the ammonia in animal slurry.

The project still under final trial phase and patent process.

Stay tuned….